TIG welding is all about accuracy and professionalism. You can make your welding more efficient while having the perfect TIG welding tungsten electrode type. So, here we come with the best tungsten for aluminum reviews for you.

TIG welding is all about accuracy and professionalism. You can make your welding more efficient while having the perfect TIG welding tungsten electrode type. So, here we come with the best tungsten for aluminum reviews for you.

What is tungsten? Well, TIG refers to tungsten inert gas. Tungsten is a small piece of heavy powerful stone. It is mostly used for melting metals. The jeweler is very attached to this stone for designing jewelry.

Welding aluminum is the hardest task for welders. Handling aluminum needs a lot of patience, perfection, and perfect tool.

If you have the right machine following the right settings then the welding becomes easier. And last but most important is to have the right tungsten.

Table of Contents

Best Tungsten For Aluminum Inverter TIG Welding

Every welder who wants a successful TIG performance might be searching for the right tungsten electrode.

So, what is the best tungsten for aluminum?

This article will describe the top 5 reviews of the tungsten electrode and guide you through all the peaks and perks.

Highlighted Features

- Easy to use.

- Recommended from professionals.

- Cheaper but offers high performance.

- Produces a stable arc.

- Ideal for inverter TIG welding.

Do you need tungsten for both AC & DC? This blue 2% lanthanated electrodes are the right for every application.

It is mostly famous for easing the arc. Else, it doesn’t require a high amount of voltage and amperage. Since it produces blue electrodes, it is extremely effective for creating alloys on aluminum metals.

It’s a well-constructed electrodes package. So, you can go for MIG, TIG, Stick, and many more with it. The best purpose to use it is the arc starts. It gives a solid high frequency in the aluminum metals. Its electrodes get started at the first moment of its starting. That’s how you get bright and clean welding.

It’s an easy-going tool for your welding. The open container packaging is user-friendly. There is no hardship to remove them from the container. You should take the warning seriously on the packaging. It strictly says not to use all those electrodes altogether. You may end up being in a mess application welding.

It holds ANSI and AWS standards for performing multiple applications again and again. It’s on our top list because of the special arc-striking. Else, do you want a low burn-rate? This is the one to create a minimum rate of metal burn.

Apart from the aluminum, this is a great tungsten electrode for steel too. The weld puddle works gently on the aluminum. However, if you want a clean weld on aluminum, this piece can be the right mate for you.

Who doesn’t want the best tungsten electrodes? This one can be the cheap tungsten electrodes for aluminum but provides the maximum features and advantages.

Still, fighting to decide which tungsten to select? Let's continue the next one.

Highlighted Features

- Quality is top-notch.

- Easy to use.

- Offers clean weld.

- Durable and spatter free performance.

- Ground finish.

Are you searching for strong and durable electrodes? This GENSSI is considered to be the premium quality of tungsten electrodes. It is ideally made for handling tougher to toughest TIG aluminum welding. If we look at the design, the design is minimal but efficient too.

While we have tested them in our workshop, the result was very fluent and clean. There was a stable arc through every welding application task. The design is made in such a way that welds with less spatter along with the stable arc.

What kinds of metals you can weld using it? This is multi-purpose tungsten for aluminum. Are you a business-minded welder? In that term, you’re investing for one but getting services for several, how? GENSSI has manufactured these electrodes with 2% lanthanated. So, it can weld on aluminum, steel, stainless steel, mild steel, carbon, and bronze too. Sounds great, right?

There are many which can’t perform on both AC & DC applications? There is no point in having multiple packages of electrodes for performing AC or DC separately. Owning these electrodes will make you free from the hassle of AC & DC. It can operate for both kinds of applications.

You’re not a professional TIG welder? That’s not an issue. These are designed for everyone. Whether you’re a skilled welder or just a beginner, this will make you go on the welding perfectly. We’ve already discussed its stable arc. So, you always get the maximum perfection in your applications.

These are the tungsten electrodes from GENESSI that have got no negative feedback till now from the users. So, you can get them now confidently. The price is cheaper and its investment would bring your success and satisfaction in your welding.

Highlighted Features

- Perfect electrodes for AC & DC projects.

- It comes with excellent caps for every electrode.

- Durable design and performance.

- High amperage control capacity.

- The ground finish is excellent.

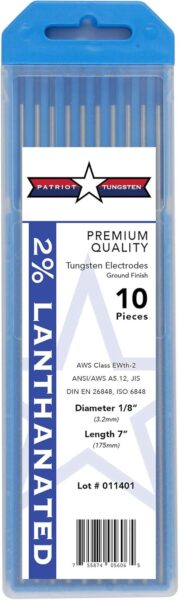

What if you’ve to TIG on titanium sometimes? Where to search for the best electrodes for titanium? There is no need to rush for now. We’re going to talk about Patriot brand tungsten electrodes which can make your TIG performance great for titanium too. Else, it works great on aluminum, stainless steel, carbon steel, and mild steel too. So, welders out there what do you think?

High amperage is something very hard to handle sometimes. However, 2% lanthanated able to handle high amperage with ease. There is no contamination to tolerate with them because there are no shattering metals. So, we loved its clean welding process.

A disturbing arc can make your project end up being in a disaster phase. But these electrodes from amplify was amazing. They didn’t create any hassling arc. Arcs were very clean and stable from starting to end.

It is highly recommended for multiple sizes of metals. You can perform using it for 3/32, 1/8, and 1/16 metal sizes.

The packaging is awesome. They come in visible plastic tubes. Else, there are removable caps of black vinyl for every 10 pieces. The caps allow the electrodes to stay in moisture state for the next time

The electrodes are long for being 7 inch longer. And these are appropriate for any aluminum type from mild to thick. Welding on steel is somehow good. But the result for aluminum is extremely satisfactory.

Till now, these electrodes can satisfy its users for its premium quality, excellent packaging, and superior ground finishing. Before being too late, get them and enjoy outstanding TIG welding on aluminum.

Highlighted Features

- It offers a long life for the electrodes.

- Produces high-quality arc.

- Durable and premium quality.

- Works greatly for inverter welders.

- Budget-friendly.

It’s obvious that you need the best tungsten electrodes for aluminum and that’s why you’re here. This is another pick that meets with most of the expectations we had for the aluminum TIG welding. It can make you satisfied like no other electrode will ever do.

The 2% ceriated is perfect for aluminum welding through AC voltage. You will get a great welding result. Else, it works great for steel and SS with DC voltage. In meanwhile, it works great for both AC & DC. Anyone who has been desperately searching the best tungsten for aluminum inverter can select this for their TIG applications.

It’s not enough to have one of the best TIG welders in your workshop. You must have to include electrodes too that carry longer life. Thus, you can bring flexibility in your TIG projects and enjoy success too.

Do you need business class electrodes? These tungsten electrodes can be the best selection then. From automobile industrial applications to beginners’ tasks, it has the ultimate power to handle anything. The hardest tasks like making frames of car, bike, bicycle, and the off-road jeep is just a cup of tea with this tungsten.

Apart from the fantastic mechanism for AC & DC, it can easily endure high-amperage. And if the welder machine circulates low amperage, these electrodes are known to perform without causing any trouble too.

If you need to work on thicker aluminum, then this isn't the one for you. It is suitable for welding thin and medium-thick aluminum. Else, these electrodes are long sustaining. So, spending a very little amount from your pocket won't make you suffer a bit. It's quite worthy to be listed for the next tool purchases.

Highlighted Features

- AMERICAN Welding Society (AWS) certified

- Electric conductivity with a low melting point.

- Easy to use.

- User-friendly design and lightweight.

- Clean welding with smoother performance.

Do you want a universal welding electrode? The YESWELDER tungsten electrodes are widely known and used among the wise welders.

Are you someone who needs to weld for hours and hours? Then definitely you want something lightweight, durable, and flexible too. These stainless-steel electrodes are going to make your welding more subtle and comfortable.

The 2% ceriated tungsten contain a minimum of 97.30% tungsten and 1.80-2.20% cerium, ceriated electrodes can be used proficiently in AC or DC processes and perform best in DC welding at low current settings.

Also Read: Best Budget MIG Welder Under 500

What Are Electrodes and Their Types?

While you want to use them, all you need to clean the surface and make sure they are polished too. Since it is lightweight and has the powderless functionality, it can easily become the favorite piece of any welder.

Before you want to select, you must know what is tungsten electrode? A tungsten electrode is a rare metal that is used for TIG welding specifically. The TIG process operates through the tungsten by its high-temperature resistance. It carries the high-voltage current to the arc. So, the tungsten can melt any metal using higher degree Celsius. Some tungsten can melt the metal even going up to 3,410 degrees Celsius.

Electrodes are a non-consumable component. They are available in different lengths and sizes. Electrodes are combined into two sections. You can either get them in pure tungsten form or oxides.

Depending on the work types, you must select the electrodes type. Else, the consistency, thickness, the material type will indicate through AC or DC flow.

How To Select The Right Tungsten Electrodes?

Tungsten electrodes are mainly known for their color patterns. Every tungsten electrode is defined by a unique color code. You will find the color on the tip of the electrode.

So, let’s identify the features and classification of every color code.

Green - Pure Tungsten:

Green colored electrodes are purely classified as the standard tungsten electrodes. They contain 99.50 pure tungsten. It indicates they can consume the highest level of electrodes. Else, if you're running on a budget, these are less expensive comparing to their alloyed capability.

Clean and powerful arc stability always occurs with these electrodes. They can accomplish AC welding following the balanced wave through the applications to applications. Else, pure tungsten is very popular for creating great arc stability for AC sinewave.

Choosing them for DC applications isn't an ideal idea. They can't provide a strong arc for DC applications. But you can use them for some small projects which are less important anyway.

Gold - Lanthanated:

Lanthanated tungsten electrodes contain 97.80 percent tungsten. The actual reason for being known as lanthanated for having 1.70% lanthana.

Welders who want a good arc starting would fall for these with the first use. They offer a minimum burn off rate. Else, there are some similar advantages to ceriated electrodes. These electrodes are widely used for increasing welding abilities. They are moderately used for AC & DC electrode.

The ball of these tungsten stays at the sharpened point for using under AC sine wave power sources. The best advantages of these electrodes are to weld greatly on stainless steel on both AC and DC from generating square waves.

Red – Thoriated:

These electrodes have 97.30% tungsten and thorium level is 1.70%-2.20%. Thoriated electrodes are mostly used among professional welders. They have a long lifespan. Else if you want easy operation for TIG, then it is the best electrodes for you.

Thorium is capable to increase the emission level of the electrode. So, your applications get a more stable arc starting. And then it can easily work through higher current flowing.

These electrodes can melt below their specific temperature. So, the arc stability remains fluent and the consumption level is always low.

During the welding process, the thorium is spread through the electrode. So, the edge of the tungsten remains sharp as usual.

Orange – Ceriated:

Ceriated tungsten electrodes tip point is orange color. They have 97.30% tungsten and 1.80 to 2.20 percent cerium component. That means these electrodes are 2% ceriated.

If you're someone who wants to perform DC welding at low current flow, then you can select them for you. Some welders also use them for AC welding applications and satisfied in terms of alloys and stable arcs.

They can ideally good for the excellent arc starting at low amperages. That's why you can enjoy delicate types of tasks like pipe fabrication, sheet welding, orbital tube joining, and other small tasks too.

It’s a perfect electrode component for handling multiple materials. You can weld carbon steel, steel, stainless steel, titanium, and nickel alloys using it.

Ceriated electrodes are ideal for only low amperage. If you want to try some high amperage application tasks, then you're recommended not to use ceriated tungsten electrodes.

Brown - Zirconiated:

99.10% tungsten and 0.15 to 0.40% zirconium is all about a perfect combination of Zirconiated tungsten electrodes. Stable arc and protection from tungsten spitting are the main features that everyone looks for.

It has a balled tip which can perform AC welding. Contamination is less likely to occur for high resistance activity. If there is no pressure of circumstances then you can try it for DC welding too.

Gray – Rare Earth:

Rare earth tungsten electrodes contain different oxides combination in one place. You will find the percentage of each oxide on the labeling. So, you'll get different results depending on the percentage of the additive.

So, look for the additive types and percentage and that will indicate if they can operate stable arc in AC and DC welding. Comparing to thoriated tungsten, rare earth electrodes have a longer life span. Else they're great for creating less spitting of tungsten.

FAQs For TIG Welding Tungsten

1: Which tungsten to use for Aluminum welding?

Answer: Since, aluminum has thin, thick, and mid-thick range types. A professional hand with the perfect welder machine can weld aluminum fluently. So, you need pure tungsten electrodes for handling aluminum materials.

So, choose green electrodes for aluminum and magnesium. Green electrodes don't work great for DC welding. They can't produce strong arcs like ceriated or thoriated electrodes can do.

2: Can I use purple tungsten for aluminum?

Answer: Purple tungsten electrodes are widely known ideal for all kinds of applications and metals. They can go on any metals like aluminum, titanium, copper, magnesium, steel, stainless steel, carbon, nickel, and high-alloyed steel.

3: Can I TIG weld on Titanium?

Answer: TIG welding on titanium is hard but easier with the right procedure. While you want to use electrodes on titanium, you must make sure the titanium piece is free from oil, coatings, and completely clean. That's when you can enjoy an easier and successful TIG welding on titanium.

4: What is blue tungsten and why it is used for?

Answer: If there is anything that has a longer life than 2% thoriated, then it is the blue tungsten. It can work great for AC and DC. It also works for inverter power sources. If you want longevity, blue tungsten is for you.

The Last Words:

Here, we’re likely to end our topic!

What was the purpose of the above discussion?

We tried to dissect the best tungsten for aluminum and provide helpful reviews that will help you to select the best one for your next welding task.

These above-described electrodes are pricey at all. So, there would be no moment to arise to break your bank account to buy any of them.

You can try the one which matches with your maximum requirements. If you want to know our recommendation then we'll suggest you get TIG Welding Tungsten Electrodes. It satisfied most of its users for giving stable arcs. Else, it has the maximum positive reviews from its users.

We tried our best to discuss A-Z details of these tiny complex metal tools. If you're still not sure what to choose, ask yourselves about your requirements.

We hope you got the right electrode for your TIG welding!

Happy Welding! If you still have any queries, feel free to comment as below!