There are a lot of people out there who are just following the crowd aimlessly. The truth is “the one who follows the crowd will usually get no further than the crowd.” However, we believe you dare to stand alone, and that’s why you are here. Otherwise, who would give a damn about knowing the types of welding joints.

To make your work stand out of the crowd, you got to know what the crowds don’t. As once a great man said, “the difference between something good and something great is attention to detail.” In this article, we will explore the planet of welding joints.

Knowing your stuff well will boost your confidence and, ultimately, your performance in work. Anyway, without further ado, let’s get it started.

Table of Contents

What Is A Welding Joint?

So, what in the world is this welding joint? You must be familiar with the term gravitational force, the attraction working between all the matter that exists. The reason why you are able to sit on your chair and, reading this article, instead of being sucked by some strange force, and blasting into pieces.

So, what does the welding joint have to do with this thing? Well, the welding joint almost plays the same role, it fits materials together. It’s somewhat also like tree branches. The point of the boughs of the tree where multiple twigs start. In this particular area of metal, wood, or plastic, multiple materials are joined together by the procedure of welding.

Types Of Welding Joint

Different types of projects, different types of welding joints. To become an allrounder in the field of woodwork or metalwork, you got to have an idea about all welding joint types. This will widen the horizon of your work.

And if you are a professional, you will be able to get more projects done and, if you are DIYer, you won’t have to hire an expert. In both scenarios, your hard-earned money is being saved. In this section, we are going to get acquainted with different types of welding joints.

1. Tee Welding Joints

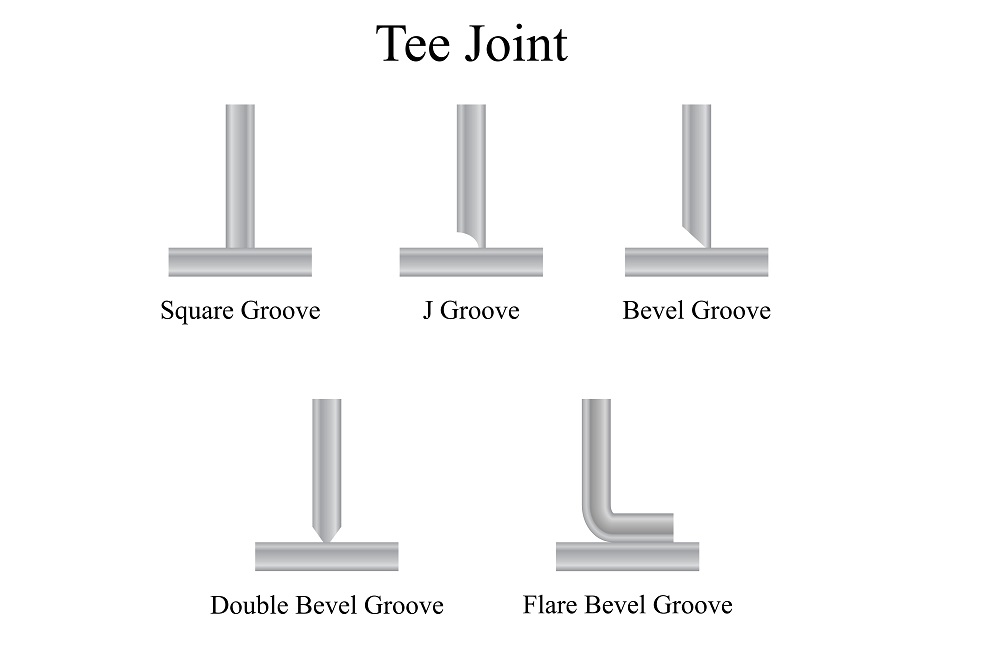

To create the tee joint weld, you need to interconnect two ends maintaining a 90-Degree angle, while one element will be laying in the middle of the remaining in the group. When the two ends are joined, it will appear like the letter T and, that’s why it was named Tee joint.

You can create this joint using tube or pipe welding at the base plate. We would highly suggest you take extra precautions to make sure the required penetration into the roof of the welding. This type of joint is usually applied to make machine and structural applications. Also, when joining tin plates. Some of the most notable tee joint styles are:

- Plug weld style

- Slot welding style

- J-groove welding style

- Bevel-groove weld style

- Fillet weld tee weld style

2. An Edge Joint

Attaching sheet metal parts having flanging edges to the adjacent joints is known as edge joints. It’s a groove-type weld. In this welding joint, two pieces of the materials are kept together then weld on the same plain. When it comes to heavier material, you will need filler material to melt and fuse in the joint. The aim here is to strengthen the base material.

You should know that this type of junction is not so strong. The reason is it does not enter through the joint completely, and you have to conduct regular maintenance. You cannot use this sort of connection in projects where much pressure is needed. This welding joint has some styles such as:

- V-Groove weld style

- U groove welding style

- J-groove weld style

- Corner-flange weld style

- Bevel-groove edge weld style

3. A Butt Joint

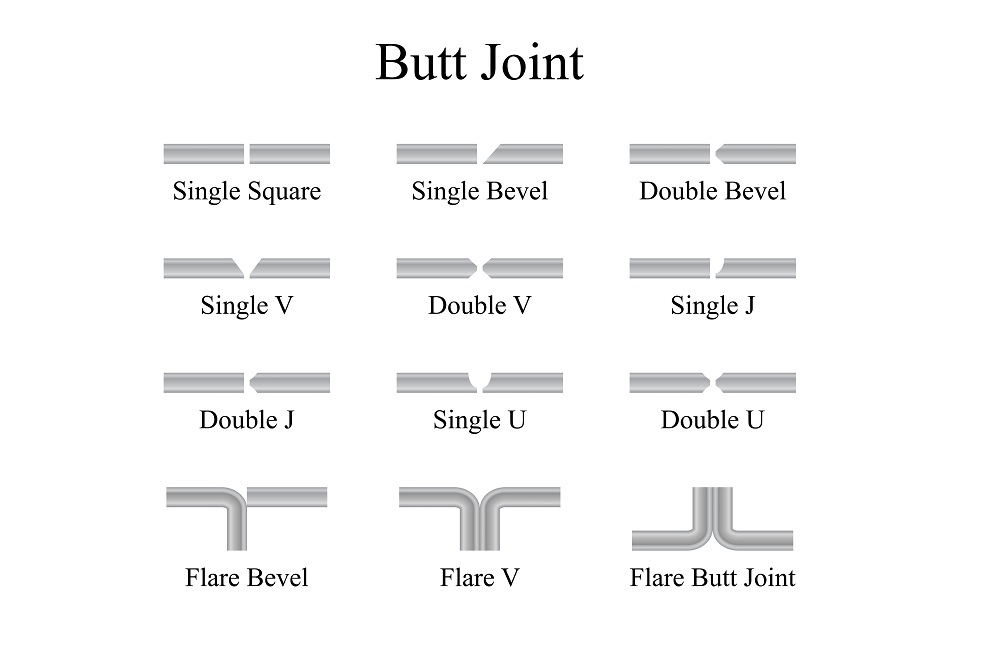

A butt welds joint is also a popular category of joint. In this joint, two poles of materials are simply joined by keeping them together. In many places, these sorts of joints are used, such as fences or building gates. They are mostly used to join weld wood or weld metal. You will see these joints extending the frames for cars, piping systems, and machinery utilities. It’s also applied in computerized methods, as well. Butt welds joints have 3-different types, and they are primarily:

- Single welded butt joints

- Double welded butt joints

- Open welded butt joints

These joints also come in various styles. Down below, we have mentioned some. Let’s have a look:

- V groove butt welding style

- U groove butt welding style

- J groove butt welding style

- Bevel-groove butt welding style

- V-Groove weld

- Flare-V-Groove Weld

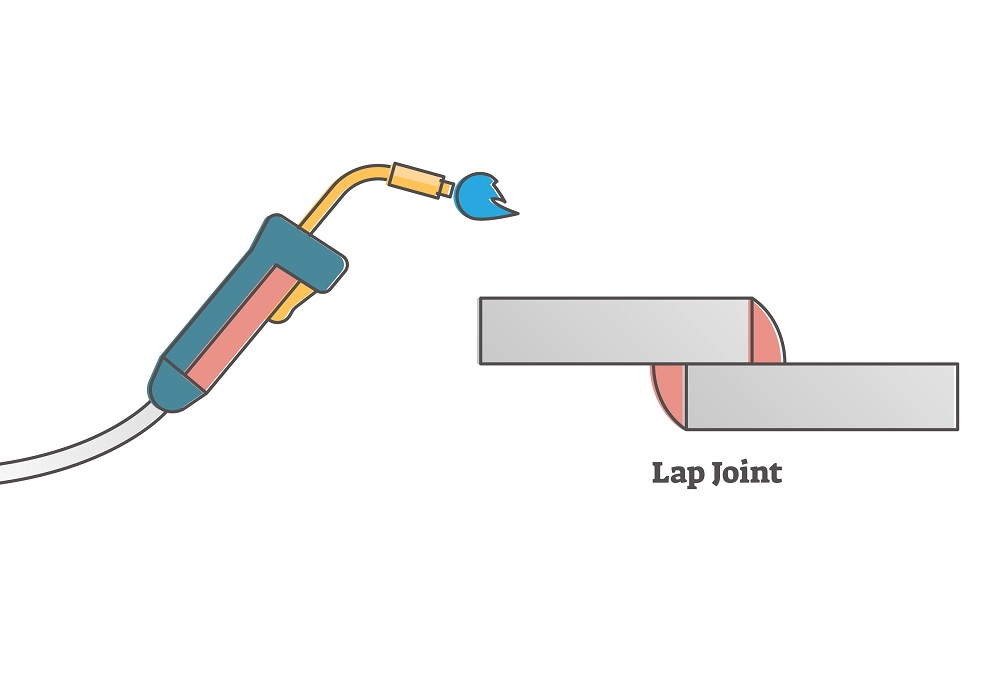

4. A Lap Joint

Lap welding joints are also very useful when it comes to joining wood, metal, or plastic. In this joint, two parts of the materials are kept one on top of the other. You can make a permanent joint or a temporary one depending on your need.

The temporary method is mostly done in automotive and airplane engines and can also be used as an alternative to bolts, screws, rivets, and nails, among others. As stable joints are applied in frames of motorcycles, cars, and aircraft fuselages, they are entirely a different business. Lap joints can be divided into two categories:

- Full lap joint

- Half lap joints

Lap joints also come with different types of welds styles as like the other joint types above such as,

- Spot weld

- Plug welds

- Slot welding

- Flare bevel-groove weld

- Bevel-groove welds

- J-Groove weld

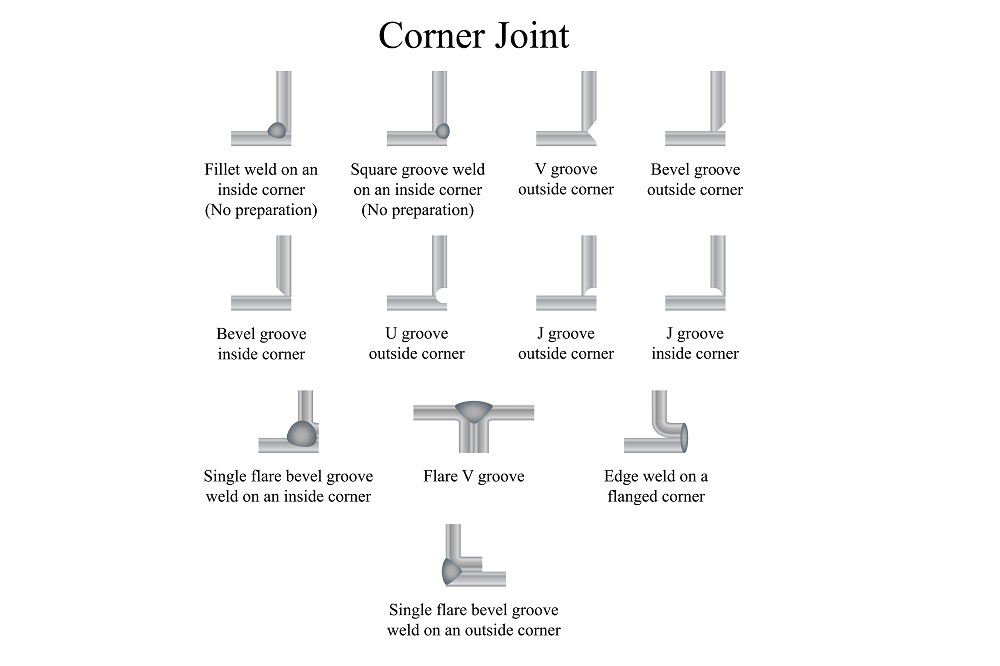

5. A Corner Joint

When you place two parts at the 90-degree position, and it forms a shape like a letter L, that’s what you call a corner joint. Don’t forget, both sides of the joint are welded. However, at times, the inner corner may not be welded. This welding joint is quite popular among welders and is typically applied to connect sheets of metal, mostly the outer edge. You will see 3 types of corner joints, and they are primarily:

- Flush Corner Joint

- Half Open Corner Joint

- Full Open Corner Joint

The Corner joint also comes in several styles, and among those, we must mention some. Here are they:

- Spot Welding Style

- Square-Groove Weld

- V-Groove

- Corner Flange

- U-Groove Weld Croner Style

- Bevel-Groove Weld

- Fillet Welding Style

6. A Square Joint

A Square Joint is also somewhat like the Tee Joint, except there’s an L, not a T. In this joint, one plate stays laying flat while another stands on its tip flush at the end of plate one. This joint does not require any fasteners, dowels, or dovetails. The flat piece of the materials have to be cut in a straight, perpendicular line so that they can make the L shape perfectly.

After that, you will need nails or adhesive to attach them. Using fasteners or springs might split the materials or crack them unless the holes are pre-drilled. The process is very easy compared to the others.

7. Fillet Welding Joint

Fillet joint is one of the most popular welding joints made by using arc welding. You would be surprised to know that a great number of other joining methods also use some techniques of fillet welded joints, such as soldering, braze welding, and brazing.

Before getting started with this method of welding, you need to consider some aspects. A common issue you might face with this joining technique is getting the accurate weld size. The fillet welding joint is quite difficult to conduct, to be honest. If you are a beginner, you shouldn’t be trying this.

Safety Measures for Welding

Whenever it comes to dealing with something that relates to fire, electricity, toxic materials or gas, sharp or heavy objects, you need to be a bit extra careful. Welding joints relate to a lot of those, so following the safety guidelines is a must. Here’re some of the measures you need to take.

- A person who understands the process must inspect the working area well to know if the work is safe and everything is at the right place.

- You must keep a fire extinguisher for immediate use.

- Do not keep any object near to the working area, which may easily catch on fire.

- You must move away from all the combustibles at least 35 feet away from the working area.

- Wear a welding helmet with a side shield to protect your vision from the UV ray, debris, particles, and chemical burns.

- Make sure you are wearing fire-resistant clothing.

- To save your hearing from the loud and harsh noise of welding, you need to wear earmuffs.

- Wear welding boots and gloves.

What matters most is knowing your work well before getting started. If you are not confident about it then, you should not get involved in it. Reach out to an expert and learn about the dos and don’ts then you are safe to proceed.

How to Prepare Welding Joints

Good preparation matters when it comes to accomplishing a mission. Before you start your welding work, there are some essential things you need to take care of. Let’s get to know those in detail.

Choosing the Right Filler Material

This is an essential step for field welding, and that is selecting the right filler materials. It has a big impact on the longevity and durability of the weld joint. There are few things you need to consider when selecting the filler material.

A technician will have to assess the material properties and chemistry of the parent material before finishing the joint and make sure both of them are complementary to make sure of the highest adhesion.

Cleaning the Joint

The next step is to clean the joint. If there’s any debris and dirt remaining in the joint, they might give you a weird finishing. You need to get rid of any oils, rust, or paint from the welding area before you begin to weld. Also, all the equipment involved in the welding should be cleaned properly before use.

Preheating the Weld Area

You cannot apply a hot welding arc to cold steel. The temperature imbalance will bring imperfections in your weld. The easiest solution to deal with the issue is preheating the parent material.

This will help you to get rid of any hydrogen, oxygen, or other gases which may decrease the quality of the weld. Without performing this action, you might notice distortion, shrinkage stress, or severe crack on the weld.

Advantages of Welding Joint

Welding joints is fundamental in the manufacturing procedure. You cannot imagine the manufacturing industry without this technique applied, to be honest. In this section, we will discuss the benefits of welding joints. Let’s find out.

- It’s a permanent joint. This helps to avoid any leakage or failure and makes a reliable joint between the components.

- There’s no chance to underestimate the strength of the welding joint. It will give you superior joint strength.

- You won’t have to drill any holes in the parent parts. So, there’s no choice but to weaken the strength of the parent components.

- The load-bearing capability of the welded components won’t change after joining.

- You can improve the mechanical properties of the weld bead to your desired level in the welding joint.

- What makes this process incredible is the option to connect different shapes such as bars, sheets, plates, etc.

- You can also join multiple dissimilar metals with or without the help of a filler metal.

- Besides metals, you can join plastics, as well.

As you can see, a welding joint has a lot of advantages. Therefore, when it comes to joining any metal parts, woods, or plastic, without any doubt, we can say this is the best option you have.

Disadvantages of Welding Joint

You know there’s a saying, “Nothing is perfect in this world. Everything has its pros and cons.” And there’s no exception when it’s about the welding joint. Anyways, let’s find some cautions, too.

- You will have to deal with metallurgical changes as the base plates need to be heated to increase temperature. After that, cool down to room temperature when welding.

- Residual stress generation will also be an issue because of the uneven heating and cooling.

- You may also face distortion of the connected structure, which can bring dimensional inaccuracies.

- The structure won’t do much well in dealing with vibrations. In long-term exposure to vibration, the joints will face a hard challenge to survive.

At large, a welding joint is an excellent method of joining objects together. What comes to play is how you do it. Therefore, if you follow the proper procedure, you are not supposed to have any big issues with it.

Application Of Welding

Welding is a groundbreaking invention of science. If you take a look at your right, left, up, and down you will find something where welding was used. It may sound silly, but it’s somewhat like a strong glue.

Whenever it comes to attach pieces of metals, wood, or plastic, the first thing you need to arrange is welding. Since the time this technology was introduced, it went through a lot of development. And that’s how it’s been able to serve you in many ways. Here are some most common welding applications:

- Different types of sheet metal & steel structure

- Fabrication of pressure vessel

- Home & automotive improvement industry

- Aerospace and aircraft infrastructure.

- Auto body repairs & manufacturing plants.

- Shipbuilding and railroads.

- Maintenance and repair.

- Joining thin metals

The list goes on and on, to be honest. Welding has been playing an unimaginable role in the development of modern civilization. We cannot finish describing the importance of it in a single article.

Why Is Welding Better Than Riveting?

There is no doubt that welding is much better than riveting. Why? Well, compared to riveted materials, welded materials are usually more efficient. And the best thing is it’s a lot easier to make alterations to welded joints. They are also more aesthetically appealing than riveted ones. And most importantly, they are sturdier than the riveted structures.

Final Verdict

Knowing the difference in welding joints is as important as knowing the process of welding. It will improve the quality of your work at a greater rate. When you have a good grasp of what you are doing, you feel very confident. This is what brings a magical flow to your work.

We hope now you have a clear idea about the types of welding joints. We do believe that you will see drastic changes in the way you work on your next projects. Fingers crossed for the best! Keep welding!