Most of the electric machines come with types. Because they tend to operate in many ways following different functions. Similarly, types of milling machines are discovered for completing the multiple cutting tasks.

Most of the electric machines come with types. Because they tend to operate in many ways following different functions. Similarly, types of milling machines are discovered for completing the multiple cutting tasks.

Since we have covered every single detail about the best mini milling machine in our previous topic. Today, we will only highlight the types and their multiple operation process.

Table of Contents

What Is Milling Machines & Their Types?

Milling is a process in an electric machine that also cuts the material like Plasma Cutters. But its process is different from plasma. Milling blade rotates in the motion ranging from higher to lower to cut wastes from the materials. You have to set it to the right angle following the right direction. While the X, Y, Z, the axis is set in the right direction, you can start your milling operation.

If we go into the depth of the milling, we can define its classification in four spheres.

- Face milling is a process of surfaces that only allows milling functionality on the flat surfaces. And only when the surfaces are positioning at the right angle.

- Form milling is another functional surface work when you tend to work with the irregular axis.

- Angular milling functioning flat surfaces circulate only at the slope or degree of the cutter’s axis.

- Plain milling functions when kept on the parallel to the axis of the cutter. It is also known as snab milling.

So, these were some milling classifications you need to know before you start working in a milling workshop.

What Are The Process Of Milling Operation?

A milling operation is a multi-tasking machine. It doesn’t only mill materials; it can turn the material also.

There is a sharp blade installed in the milling machine that rotates to cut waste from the materials. Once you’re done with the milling process, keep the machine for cooling down. Then you can remove/adjust the blade in the milling machine.

However, we’re going to describe the process of milling cutting.

Milling Cutters:

Milling cutters are designed to have surfaces. They are easily adjusted with the workpiece for cutting. Do you have to deal with peripheral milling often? You don’t need to worry. Milling cutters include cutting surfaces on every side. So, you can easily perform every type of milling.

Else, there are small cutters attached in the end corners. These small cutters produce less amount of friction. Because the highly resistant materials are used for their manufacturing.

Surface Finish:

You will notice ridges on the side cutters. They help to get regular intervals while cutting materials. Else there is a minimum distance between the ridges. The distance is calculated according to the feed rate. The cutter diameter and number of surfaces produce flexible variations in the surface height too.

Gang Milling:

Gang milling occurs when you are doing horizontal milling. This happens when more than one milling cutters are joint together. It comes handy when similar or duplicate parts are needed to be produced.

Milling Machine Types:

There are many types of milling machines. But now we will highlight 7 different types of milling machines which are mostly used.

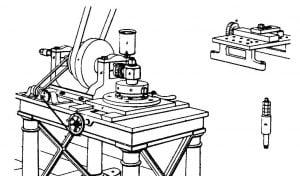

1. Vertical Milling Machines

This is a milling machine that has a vertical axis. Even if it rotates it stays on the same axis. The vertical spindle axis extended whenever needed to perform another mechanism like drilling.

Vertical mills are equipped with two additional features like turret mill and bed mill. You can perform them by lowering or raising the quill.

2. Turret Mills

Turret mill comes with a special table. It always moves perpendicularly and parallels to the spindle axis. These mills are also known as Bridgeport-type. You can reposition them anytime. Because these are very functional table mills. That’s why it has a huge impact on the automobile industry.

3. Bed Mills

While the bed mill moves perpendicular to the spindle axis and then the spindle rotates parallel to its axis. And its table is placed in the middle of the bed. While most of the mills have their table on the top.

4. Horizontal Milling Machines

This operates in the same way as vertical milling machines. Horizontal mills come with rotary tables that let the operator cut through various angles. You can use the tools for horizontal mills that were used for vertical mills. In horizontal milling, cutters are placed in a horizontal position. Horizontal tables are also known as universal tables for their enormous usage.

5. Column Milling

The column is hugely known and popular among many workshop owners. It is very small in size and handy for professional tasks. If you’re someone from the automobile industry, then you must get one of them.

There are 5 basic parts you will see in it. The work table, over arm, saddle, head, and knee are all the things that configure a column milling. It’s so easier to operate and the first choice of many out there.

6. C-Frame Mill

C-frame mills are mostly seen in industrial purpose use. They are big and perfect for accomplishing heavy-duty tasks. Its special feature is vertically moveable knee and spindle head. Comparing to turret mill, it is more powerful.

This requires a hydraulic motor producing excessive power in all directions as it comes with a 20-50 hp motor power. The tables of the C-frame mills are larger measuring 18″ by 68″. They come handy when you need to work with multiple workpieces at once.

7. Tracer Controlled Mills

We consider it a special mill for holding the ability to reproduce duplicate pieces from a master model. This is vastly used in the automobile industry. It makes the production of the parts easier and much faster. So, you will see these mills mostly in the automobile production workshop.

The Last Words

You can’t say enough about the classification until you use it yourself. You have to understand your requirements. The most important key factor is to utilize a machine to get the best from it. Until you don’t have the utilization skill, don’t decide to pick a random milling machine.

Because it will just give you confusion and hassles. To get a higher level of benefits, make sure you’ve enough skill power and determination. Only then you can make the best use of the milling machine.