How to use oxy acetylene torch for heating the metal perfectly is still a mystery to lots of welders. Because it’s one of the most widely used heating and cutting but welders are struggling to get used to it.

How to use oxy acetylene torch for heating the metal perfectly is still a mystery to lots of welders. Because it’s one of the most widely used heating and cutting but welders are struggling to get used to it.

We are here to reveal the heating process that you are looking for. It is not rocket science to understand. But this is something you must keep in your grip. Few parameters like using a pressure reducing regulators, torch flame, connecting gas supplies are the key parts you should master.

For safe welding practice, we come with this detailed guide for you.

Table of Contents

How To Deal With Massive Heat?

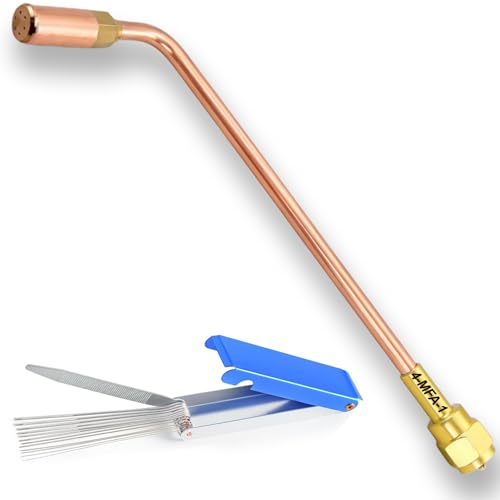

The oxyacetylene torch is capable of heating and cutting through a simple flame. A flame that can create massive heat. Using an oxy-acetylene torch for heating and cutting becomes a universal truth for welders.

As a versatile tool, it comes as an affordable option along with some tremendous and effective heating techniques. This guideline will help you to make perfect sense of how to use oxy-acetylene torch for heating. Trust me, it’s not as hard as you think.

The mystery of Oxy acetylene:

As we mentioned, the mechanism of Oxy acetylene is capable of producing massive temperature. It easily exceeds 3000 degrees C.

Pure oxygen and acetylene make a perfect combination to produce such flame for heating. This mixture helps to heat any type of metal and helps to reach its perfect melting point.

It seems easy, but an inexperienced hand can burn as well as explode everything. So, we are going to address a few steps for both professional and beginner welders.

Oxy-Acetylene Cutting Torch Pressure Setting

The Oxy acetylene torch is also known as a blow torch. People give this name because it’s a great solution for heating metal. Without proper use, it seems difficult for many people.

At first, you have to deal with proper settings. Do you have any idea about it? The proper use of the torch depends on the pressure you are going to set. Controlling the pressure defines the quality of heating and cutting you are going to make.

Right pressure makes the heating process quicker and effective. Even it’s essential for safe operation as well.

Set Up An Oxy-acetylene Torch

Before you start to use the torch, make sure that it’s fully set as needed. The blow torch functions with the help of different components. But every component must be perfect. To minimize the risk of any kind of accident, follow the steps I’m going to discuss below.

- First of all, keep the cylinder or tank in an upright position. Make it fully secure in this position. If possible, fastened or chained with some solid and sturdy object or use a cylinder cart.

- Remove everything like debris or dust that is covering the valve. Because such things can settle inside the valve. This is the reason the valve malfunctions. There are tips you can follow to do it. Turn on the valve quickly and close it again in less time. But stand away before doing it. This method will blow all the dust and debris with the blow.

- After matching the thread, connect the valve to the regulator. If needed, use an adapter and make it completely tight using a wrench. This regulator will help to monitor the pressure.

- It’s time to attach a hose. Ensure all the hoses are perfectly attached to the regulator. For better practice, we suggest you use hoses of different colors like green for oxygen and red for acetylene.

- Take the torch and connect the handle with hoses. Now install the cutting torch. Check again and again all the connections are secure with the valves, cutting torch, and handle as well.

- Keep your eyes on the pressure gauge and turn on the valve of the oxygen tank fully. Control the adjusting screw of the regulator. Keep the pressure between 40 to 60 psi. On the other hand, you need to turn the acetylene cylinder counterclockwise for only a quarter. Keep the pressure 10 psi.

- Now, let’s flow the oxygen through the torch. Open the oxygen valve for this. Follow the same procedure for the acetylene. Be Careful, to do it. You shouldn’t do it more than 45 degrees.

Light an Acetylene torch

It’s time to light the acetylene torch and believe me, it’s fairly easy to do. If both materials (Oxygen and acetylene) have the psi, that needs for flaming, then it just needs a spark.

- To create the flame, open the valve of acetylene. It should be half-turn.

- Don’t use any light to torch. It’s too risky to do. Otherwise, you’ll burn yourself. Use a lighter or own ignition system of the torch.

- First, you’ll see black smoke with the flame. Now open the oxygen valve slowly until you’ll see a yellow and neutral flame.

- After getting a neutral flame, the bright blue center will appear. This is the core you need to heat and cut the metal.

Using An Oxy-acetylene Torch For Heating

After lighting the torch you must heat the metal. This is an obvious task to do. Heating is the preparation of the metal for cutting.

You don’t need to press the torch lever to heat the metal. The flame is enough to do it. Now apply the flame on the point of the metal.

Do it until the section of the metal turns into a bright cherry red color. If the heat is not enough to make the metal soft enough, then press the lever to produce more flame.

Heating becomes more effective when you start it from the edge of the metal. But you can do it at a specific point of the metal. After completing preheating, the metal is now ready for the next action.

Conclusion:

Professional degrees cannot make you specialized in the use of an oxy-acetylene torch. If you don’t get some hands-on advice but want to learn how to use oxy acetylene torch for heating from a simple flame then you’re in the right place.

Remember, playing with flames is not a child’s game. But following the process that I’ve discussed earlier can make it easier than everything.

It is not possible to consult with professionals all the time at the time you need. That’s why this guideline is for you. It won’t help you to be a professional welder but surely helps to deal with the torch like a pro.