After a lot of tests and usages, our professional team has come to a final list of the top 5 best mini milling machine. If you’re here to search for a masterpiece mini milling machine then you’re at the right place.

After a lot of tests and usages, our professional team has come to a final list of the top 5 best mini milling machine. If you’re here to search for a masterpiece mini milling machine then you’re at the right place.

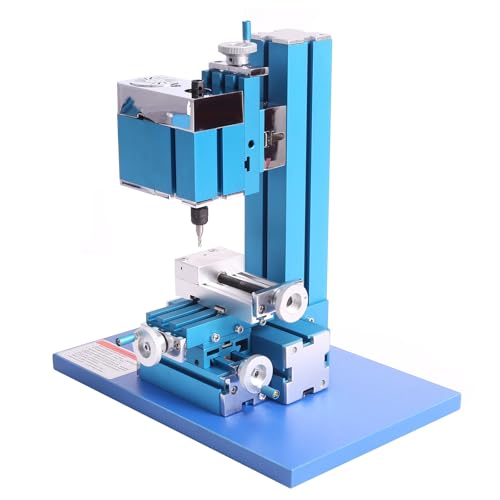

Mini mills are the most powerful tool to make an uneven surface into a flat surface. That means you can get a flat surface on the scrap materials and use them for various purposes.

So, it’s high time to forget about the old-fashioned hammer on to construct a scrap piece into a handy material for your workshop. Because we can rely on “Milling Machine” the greatest invention of the latest science. It makes our harder tasks easier like making versatile surfaces, drill, bore, slots, and many more.

And we shall proceed to the final list of the best mini mills afterward now!

Editors Picks

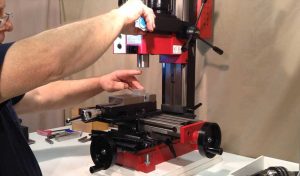

Among all the miniature milling machine, Grizzly G0704 offers more than we are seeking! This won the battle of being our editor’s choice after multiple test drives.

It provides flexible performance on the materials. Whenever you need to perform a damage-free operation, it has no comparison. It comes with a lot of modifications and functionality. One of the best modes that we’ve liked is CNC mode. The CNC program makes it more versatile and flexible to use in both the workshop and home.

Table of Contents

Quick Chart For The Mini Milling Machine

Product | Weight | Style | Power Source | Price |

|---|---|---|---|---|

739 pounds | Mill/Drill | Corded-electric | ||

143 pounds | Mill | Corded-electric | ||

416 pounds | Mill/Drill | Corded-electric | ||

140 pounds | Mill | Corded-electric | ||

342 pounds | Grizzly | Corded-electric |

Top Reviewed Best Mini Milling Machine (Industrial Grade)

Since you know our editorial choice, still you want to choose from the many. And it’s better to get machinery after a lot of research. That’s when you can select a cool tool or machine for your workshop.

So, here we are going to discuss best features and advantages of the top 5 best mini metal mill.

JET JMD is the best industrial milling machine that comes handy for any professional. While professionals have to deal with different types of materials such as wood, steel, aluminum, and ceramic tile too. As long as you need to handle versatile materials in the workshop, it has no better alternative.

It comes with a larger dimension worktable. You get the freedom to manage the bigger pieces of scrap on the table and work on them easily. Therefore, you get the versatility in your workspace. And that’s pretty amazing for the professionals to handle bigger tasks.

A work lamp is offered by Jet manufacturer to make the operator work in any conditions. Whether you work in dimmest worksite or under no light, its work lamp provides ample illumination. Hence, you can apply the right posture on the component.

It is more powerful than other milling machines of our list. Its 2 hp makes the hardest cuts easier. The powerful motor will deliver you the exact result you’re looking for.

There are some additional things come with it. The heavy-duty tapered roller bearings are one of them. It brings flexibility while you work. Else there is a hinged belt cover that also comes extra. It changes the speed whenever you need to control it.

The depth gauge is easy to understand and you can easily maintain it. While some other manufacturer requires high-maintenance and professional’s hands to operate, you can operate it without having any pressure.

Pros

- The powerful motor offers flexibility and versatility.

- Performs both milling and drilling.

- Easy to operate.

- Sturdy construction that lasts.

- Assembling and maintenance are easier.

Cons

- The stand doesn’t come with it. So, you’ve to order it manually.

It’s durable and powerful and worth to invest your money in it. If you go through jet milling machine review, then you will see it lasts till the end until you make any malfunction activity by yourself. And the best thing is it costs less that it offers!

Who doesn’t want a durable mini mill? This klutch machine comes in a very solid state. It is made with cast iron. So, the whole body is hard enough to endure any kind of solid material. If you’re paying for it, you’re paying for a sturdy and durable machine that will last and last.

The cutting ability is greater because it cuts through the hardest materials. When the machine exceeds its cutting ability it automatically shuts down. Thus, there happens no burning incident. So, the motor supply remains fit for years and years.

The vibration level is low as you’ve never imagined. You will barely feel the vibration on the table. Therefore, you can enjoy a smoother work experience.

Else the motor is powerful for 2 hp power. The motor operates on 110V variable speed. And there is a 2-speed gearbox that provides 350W. You can get the bigger convenience in your work if you wish to add CNC motors. The CNC motors will allow you to do some bigger cutting task which is not possible with the ordinary one.

It comes in a fully assembled condition in the box from the manufacturer. Though it comes with 2 T nuts you have to buy an additional clamping kit. The clamping kit will able to secure the table and materials.

You can use this benchtop milling machine for your occasional hobbyist tasks. This is an ideal milling table that can afford smaller professional task easily. But for the bigger task, it may stay behind to fulfill all the requirements.

Pros

- Comes with a direct-drive motor.

- A drill press is in an assembled form when arrived in the box.

- Easy to operate.

- Durable and compact design.

- The powerful motor offers convenience work.

Cons

- Not applicable for workshop heavy-duty task.

Hobbyists or beginners who want affordable mini mill with the maximum features and compact durability, they can go for it.

The SHOP FOX M1111 is a modified version of M1110. It has all the features of the M1110 and some additional features made this milling in our list. From the powerful motor power to headstock movement, everything is quite efficient than the M1110.

Vertical milling operation is mostly present in all the mini mills. But horizontal milling is something so rare to find. Surprisingly, this SHOP FOX brings the quick-tilt headstock for horizontal milling.

Its 1 HP brushless DC motor performs on 110V operation. So, every user gets satisfaction clean cuts for the powerful motor. Though the weight is 440 pound, it can be lifted and down with the adjusting head up and down. It is easier to lowering the head but raising the head takes some hand pressure. However, you don’t need to operate both hands. It only requires one-hand operation and is user-friendly according to us.

It is more likely to be a knee mill. You can control its base using a hand wheel. Also, you can level up it without fastening down. So, maintaining this mill is beyond easier than you’ve ever thought.

It doesn’t come in a sticky red grease like other manufacturer send their tools. You get it in the light coating which can be easily wiped. So, the first impression is amazing when you unwrap it from the box.

Pros

- Lowering and raising the head is easier.

- Less vibration.

- Powerful performance from the 1 HP motor.

- Flexible for both home and workshop projects.

- 110V runs on home power outlet. So, no additional power source is needed.

Cons

- The table size isn’t reliable for bigger projects.

SHOP FOX M1111 is just for those who want a flexible but durable milling/drilling machine. It co-operates with the operator in the mill and provides outstanding cutting experience to the user.

Well, OTMT OT2213 is another best mini metal mill in our top list. It comes with more features than we wished for. The motor runs on 1/2 HP. So, you can able to perform harder heavy-duty milling and drilling following a couple of steps.

While we reviewed it, we were completely surprised for the variable speed control. It has dual speed ranges.

The higher range offers you 1100 to 2500 RPM. It offers the machine to do all those heavy-duty tasks without any hassle. Its low range offers 0 to 1100 RPM that let you perform smaller home projects. Therefore, you can use it for the smaller hobbyist task to professional workshop tasks.

There is flexible dialing which is easy to read that the result in the accurate cut. It can even give 0.0001-inch cut on the materials. So, this is a weapon for those who tend to work with delicate cuts. The head can rotate 45 degrees. So, the cut is more precise and controllable.

Its table size is enough big to continue sizing your larger scarp pieces. The only problem that you will face is its slacks in both x and y-axis. The slacks are fine until you’ve to rebuild the table to get rid of them.

Pros

- Dual speed ranges.

- Powerful motor with the variable speed motor.

- Flexible for milling and drilling.

- Head rotation to 45 degrees to both directions offers flexibility to work.

- The table dimension is larger.

Cons

- Slacks in the axis cause some interruptions.

If you want a bigger workspace table with great motor power, then this is the tool for you! Apart from the slack issue, this is worthy of your money and time.

This grizzly milling machine maybe in our last pick but have more than the essential features. It is very much similar to JET but has less motor power. It runs on 1 HP power and doesn’t provide a higher range of RPM. So, you can’t use this for the industrial type tasks.

Still, hobbyists out there can enjoy its advantages in extreme extend. And you can add a larger motor to it and operate for heavy-duty tasks. You can order an extra drive belt, some DROS, and CNC to make it a pro. The counting dials are not so easier to co-operate with. But if you do these changes in the mill, the counting dials are going to be also flexible.

There are a lot of changes and modifications you can apply in its settings. If you get a CNC, this machine can also operate on CNC modes. Just a couple of steps and you can turn this grizzly milling to a best CNC mini mill.

The DRO quill gives awesome satisfaction for the Z movement. However, the thickness should be less than 1.5″. You may experience issues with the layout cutting operation. But this machine works perfectly on the X and Y-axis. Whatever issues you face with axis dimension, you can solve them by checking the web.

It is flexible to carry. Because its weight is lighter than other mini mills. The table size isn’t larger. Hence you can only work with smaller pieces.

Pros

- Perfect for a manual conversion.

- Able to perform CNC after upgrading.

- The turn off switch is safe to use.

- Head can rotate to 90 degrees in both directions (Left & Right).

- Recommended for minimum weight.

Cons

- The plastic grip isn’t durable.

If you’re searching for the best manual milling machine, then this is the piece for you. You can do a lot of modifications like CNC and motor power. So, you can get maximum functionality in the milling operation.

What Is a Milling Machine?

A mill or drill machine operates that can-do milling and drilling. So, a machine which can do milling is a milling machine. And it is also known as the drill press. It can make holes on the workpiece. So, you will get vertical holes with the milling activities.

How Does The Milling Machine Operate?

There are rotary cutters in the milling machine that remove the wastage from the scrap workpieces. It has also the functionalities of the drill machine. Because it also provides drill press. There is some difference between milling and drilling. In the mean term of mill v/s drill, there are also some similarities.

So, when you purchase a milling machine, you get both drilling and milling features in one machine. In the milling industry, CNC cutter milling machine is the best drill milling machine in terms of affordability and flexibility.

Things To Consider Before You Buy A Milling Machine

So, you are still confused, right? Since our top 5 list only tells about their advantages and disadvantages. But you still don’t know how to get the best mini milling mill with the maximum features and advantages.

So, there are some essential things to look for in a milling machine. Let’s know them!

↠ Motor Power:

It’s quite obvious that the work performance depends on the motor power of a milling machine. Any machine works according to the motor’s capability. And then all other parts impacts the performance.

You have to choose the mini mill that can co-operate with your materials. Steel, brass, copper, aluminum, or mild steel require different power to work with. If you’re going to work with only with metal and you know that for sure then you should go for the specific mill. Make sure to choose a versatile mill to perform several materials if you’re a professional.

From our list, you can choose one for your multi-material milling. Remember, the harder materials you’re going to deal with will require for the powerful motor power. For the harder materials, we can recommend you JET from our first pick. Because it has the high-power motor capacity with variable speed.

↠ Horsepower:

Horsepower for heavy-duty tasks isn’t only needed. You will need a minimum of 1 HP power for any DIY task. Though you’re only going to deal with home DIYs, you should get 1 HP.

In this case, we recommend you Grizzly from our very last pick. So, you can easily do your small tasks with a 1 HP motor. But 2 HP is required for harder and larger tasks.

↠ Speed:

Speed is the fact that performs the milling and drilling smoothly. If the speed isn’t enough for material then you can never get the satisfactory cut and hole in metals. From wood to copper, every single piece needs a different speed range to complete the milling.

Since we have mentioned about RPM in our top 5 best mini milling machine reviews already. So, let’s talk about RPM again now. Each of our reviewed milling machines has RPM range. As far as concern for the speed, higher RPM ensure more speed and lower indicated less speed.

An ideal machine will allow you both higher and lower RPM. Your workshop needs dual RPM built-in settings in a mini mill. Because that’s when you can accomplish the various task without facing any difficulty.

For smaller projects lower RPM is sufficient. However, variable speed is still needed for the small project to deal with multiple types of materials.

↠ Table:

Milling is incomplete without its table. So, you need to get milling that has a larger table size. Without a larger table size, you can never get the same amount of flexibility in your operation that you want.

Else, table quality ensures the capability for offering durable work. If you’re going to handle some heavy-duty industrial grade, the table must be sturdy. Most of the milling table is made of aluminum or steel.

You also should look for the T-slots which installed on most of the milling. T-slots are very necessary for holding down the materials you’re going to work with.

↠ Tilt Accuracy:

The milling machine has to tilt according to the cutting requirement. Every milling has its range of tilt from 45 degrees to 360 degrees.

The rotation of the head is very much necessary when you want to cut a bigger workpiece. So, you should check out the tilt capacity range according to your work requirement.

Safety Precautions To Take while Operating Mini Mills

Safety comes first! Therefore, our team of professionals will recommend you to follow some very crucial steps for your safety.

- Once you’re determined to play with CNC, MIG, milling, or other electric tools you always should pay attention to your safety. Because they can easily harm you or sometimes lead you to death. Make sure you’re getting goggles, mask, and apron-wearing on before you start with milling. Because you any chips from the materials can get into your eyes or body.

- Make sure the current load is normal. Because a short circuit can destroy your whole project as well as you.

- While you work with the benchtop milling machine, make sure it is bolted down. Since the benchtop mini mills are bound to move from its place during the operation. So, we always recommend you to work bolting it down unless you’re a pro in this work.

FAQ of Mini Milling Machine

Here are some FAQ’s that will erase your confusions over the milling issues!

Question 1: What is the best manufacturer that produces the best mini milling machine?

Answer: Actually, there are many reputed companies producing milling machines. They don’t have that much difference in terms of picks and perks. When you’re really on the go situation with one, understand that’s the one made for you!

Question 2: Is the drill press or milling machine the same?

Answer: No! They aren’t same. A drilling machine doesn’t have bearings to endure side load. But, a milling machine has. Every milling is a drill press but the drill press isn’t a milling machine. Got it?

Question 3: Which milling machine is the best – expensive or pricey?

Answer: There is nothing to clarify actually. Who cares for the price actually when you’re satisfied with the cheapest one? You should only seek your satisfaction and durable work. Only then you can get the best milling experience.

Question 4: Is there any types of milling machine?

Answer: There are 7 types of milling machines -turret, horizontal, column, C-frame, tracer controlled, planer style, and bed type.

Question 5: Can I modify It?

Answer: You can modify it installing different types of parts like CNC, extra motor, driver bolt, and many more.

Final Words

We’ve reached the end of our reviews. Think over again and ask yourself “Do you need a mini mill”? It’s obvious that you need and that’s why you’re here. If you’re still not able to choose the best mini milling machine for you then you should go through the buying guide.

Remember, there is nothing called best in this world. You only get the best one when you enjoy working with anything. Your satisfaction and flexible experience crown a tool best.

So, purchase the one which can fulfill your maximum requirements.

Cheers to Milling!