Every beginner welder must have the best flux core wire in the workshop. It is pretty much similar to MIG welding process. Flux core wire has an automatic or semi-automatic arc procedure to weld materials.

Every beginner welder must have the best flux core wire in the workshop. It is pretty much similar to MIG welding process. Flux core wire has an automatic or semi-automatic arc procedure to weld materials.

Welding is always a tough job unless you know every peaks and perk of it. As we already know welding is a special method to join different types of metal altogether.

But, if you’re a beginner at welding you can use flux core wire method. Because this is an easier and flexible method for novices.

Arc welding doesn’t even require gas for the operation. So, this is also a cheaper option for welding tasks.

Editors Picks

After reviewing more than 30 flux core welding wires, our team of professionals locked their choice at Forney 42300 Flux Core Mig Wire. Professional welders always need to endure extra headache for choosing the best component for their workshop. Finally, they can get rid of extra burden getting this Forney flux wire.

You can use this on any kind of materials whether the material is dirty or rusty. All we can say, this is a real junk to deal with the heavy-duty arc welding tasks. You can run your business like a pro making this a daily-life welding partner. Because it provides the best speed range for welding any kind of rough metal.

Budget Pick

INETUB BA71TGS is less pricey with maximum features. If you don’t want to spend a lot of money, then you can get this flux wire. You can end your search here for the budget-friendly best flux-cored wire. This provides better performance with a 20% duty cycle. You can easily weld up to 1/4″ for its powerful wire feeding.

If you want to weld thin materials, then this one can satisfy you to achieve what you want. Luckily, this wire is eligible with any kind of MIG welder machine. So, you don’t need to worry about what kind of machine you’re using. You can just get this and go on the mission.

Table of Contents

Comparison Table Of Flux Core welding Wire

Product | Weight | Size | Installation Method | Price |

|---|---|---|---|---|

Blue Demon E71TGS .035 X 1LB | 0.32 ounces | 0.035” | Gas-welding | |

WeldingCity E71T-GS Flux-Core | 10 pounds | 0.030″ | Not-Required | |

LINCOLN ELECTRIC CO | 10.2 pounds | 0.035” | Gas-welding | |

Blue Demon 308LFC-O X .035 X 1 | 1.14 pounds | 0.035” | MIG welding | |

Forney 42300 Flux Core | 2 pounds | 0.30” | MIG welding | |

INETUB BA71TGS | 2.2 pounds | 0.30” | Gas-welding | |

Hobart H222106-R19 | 1.17 pounds | 0.030” | MIG welding | |

Blue Demon E71T-11 X | 10 pounds | 0.035” | MIG welding | |

Kissel USA K-NGS E-71TGS | 10 pounds | 0.035” | MIG welding | |

ER70S-6 – MIG Mild | 35 pounds | 0.045” | MIG welding |

Top 10 Best Flux Core Wire Reviews For Professionals & Beginners:

There are many reasons to be in the welding profession. Once you’re in this profession, you’ve to get associated tools for the welding tasks. One of the most important and necessary tools is the flux-cored wire.

Most of the welding machine comes with flux wire. But what if your welding machine doesn’t provide the additional wire for arc welding?

So, it’s very obvious to search for the best reviews and select the best one for you.

Are you a hobbyist or a professional welder? Blue Demon is flexible for the small DIY tasks to professional welding.

This is a cheap option but with a higher range of flexibility. This welds greatly without creating a big amount of smoke and splatter. Less amount of splatter keeps the arc on the right consistency. Else, the users get a satisfactory result while welding glass components.

If you don’t like to involve your welding tasks with gas, then this makes a great difference. It doesn’t need gas to be operated.

This is a great tool for not creating a mess around your workstation. Therefore, you don’t need to clean a lot of mess after you’re done with wiring.

If you’re running a 110V welding machine, then your wiring tasks will be great with 0.030 wire rather than 0.035 inch. Because 0.035 needs the extra voltage to run at high speed.

You need to get an extra 10lb spool and spool adapter for the further welding. As this wire doesn’t come along with additional tools.

Pros

Cons

You’ll be impressed with its first look! The manufacturer drives the wire in a tough Mylar bag. And it delivers in a nice state that you will love its first glance. Remember everything you love in your first glance gives you overall great experience.

Whatever, this flux wire will change your welding experience. Because it can weld providing the cleanliest surrounding you. Every user of it has been satisfied with its cleanliest welding process.

So, there is no mess waiting for you after the wiring is done!

Smooth feed makes a flux wire flexible and user-friendly. Gladly, its wire feed runs smoothly and weld durably. The splatter is also produced in a minimum length.

Sometimes the wire gets stuck on the spool gun and this makes the user very annoyed for the during the process.

The packaging comes with a one welding wire spool which runs without gas. So, there is no extra cost you’ve to experience.

Pros

Cons

Lincoln is always the best choice for professionals out there. Most of the professionals love to work with DEWALT, Lincoln, and Hobart tools from the hundreds of collection in the industry. There is a great reason behind it. Though, Lincoln cost a bit more but it gives beyond the limitation.

If you’re a welder who has to weld galvanized steel? So, you should get this tool for your work station. Because this tool produces less splatter comparing to other wires. Even you can get the maximum required result with a single pass. So, the welding process is smoother while working with it.

Professionals have to work with rusty, old, and rough metals. To handle these kinds of metals, you only can’t co-operate with professional hands. Professional hands only can provide the best result when combined with a great tool. Ans such a great tool this is!

You can easily handle rusty and sturdy materials and makes the workshop welding flexible like it never was!

The one more thing that we really can’t ignore is its larger wire diameter. Professional can never work in limitations. Thus, this will provide them excellent performance. If you want then you can get a larger wire feed welder that can be applicable with larger wire diameter.

Pros

Cons

It’s a solid stainless-steel flux core. It is a legit weapon to be a part of your welding tasks. You can weld using it without getting any rust. So, whenever you’re doing any hobbyist task, you can use it for getting a satisfactory result.

Whenever you’re using it for the heavy-duty tasks, make sure the surface is fresh. Otherwise, the splatter may occur in between the operation. That means a planned ground will not let you experience any splatter.

Though you’re going weld mild steel that requires lower power settings, you’ve to operate in higher settings while you’re using this welding wire. It takes more diameter mild steel wire even you’re welding in the same weld. Hence, it uses more power and diameter comparing to other flux-cored wire to accomplish the same task. So, you have to weld in 220-240 Volt while you’re working with any mild material. Otherwise, the expected result won’t occur!

If you’re going to work with stainless steel, then the wire is an exact choice. This wire requires gas-welding installation and minimize the splatter. Without using gas may end up making you suffer a lot of splatters. This is a heart-broken for those who don’t get helium easily in their towns.

Pros

Cons

Though it’s in the 5th position of our reviews, this one is the most favorite tool of our professional team members. You hardly will get any reason to complain to the manufacturer. It’s a king tool in its ways.

You can deal with your hobbyists, automobile, mechanical repairing, or workshop professional wiring weld with it. So, you don’t need to get multiple welding wire for a different purpose.

There is a little bit of dragging flow but it doesn’t bother the user much. While the other wire’s slag doesn’t come off easily, its slag easily comes off.

It doesn’t splatter much on the materials. But when you’re welding finished metal, it may splatter a bit. Still, it welds nicely on the materials.

You can get a great weld though you’re in a hurry. It also works fine when you don’t use a MIG gas bottle. But gas welding makes minimal splatters. So, the performance becomes more convenient.

Pros

Cons

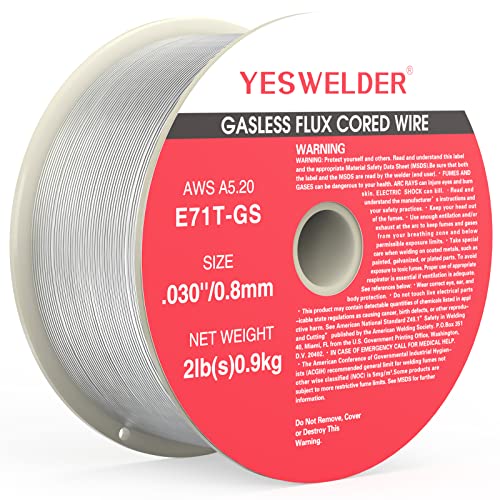

If you’re searching for a best .030 flux core wire, then you’re at the right place. Professionals who are engaged with multiple work fields like fabrication workshop, welding, construction works, aircraft, automobile industrial tasks, hobbyists and ranching, should get this wire. This is a great flux core welding wire. You can perform your basic farm and workshop’s heavy-duty tasks with it.

It welds easily and perfectly removes the slag. The heat penetration gives perfect variable flexibility, and the arc works in the consistent form. So, you don’t need to fear of excessive duty cycle.

If you’re fond of excellent welds then this one is the solid one to offer you such sensation. It alone can give you freedom from all the welding issues.

You’ll be loved to stick with this tool for its larger puddle. It splatters less and works for a hard situation with too thin materials. So, you will love to work with it for the smoother welding process.

Though this offers a gasless welding process, it is more like MIG welding. So, it allows you to do your works in easier steps. The smooth beads are quite effective to make the welds cheaper and more durable.

Pros

Cons

Are you searching for a low pricey high-quality tool for MIG welding? Well, who can offer you that except Hobart? Hobart H222106-R19 is a promising welding wire for handling a strong situation. This is the perfect match while working with the Hobart Handler. It provides more powerful and strong welds then.

It is a real flux core wire with minimum splatter on the mild steel. And works greatly under pressure and hard situations. Multiple passes with a higher duty cycle are also very flexible to be handled under extreme conditions. And that makes it a most user-friendly tool among many cheapest options out there.

This comes with a 2-pound spool that impacts on the overall performance with positive vibes.

Pros

Cons

Who does like that buzzing sound around him? While some of the most renowned companies fail to offer sound deadening welding tool, the Blue Demon E71T is offering you the best sounding wire. A good wire makes a lot of difference to your works. So, this one is worthy to get!

It comes in a very clean and professional state that you will enjoy welding with it. This gives the extremely perfect weld with clean-burning.

It works smoother and creates a minimal level of splatter. And the most vulnerable part is that you will hardly see any slag. There is a little bit of slag appearance and that can be removed very easily.

Pros

Cons

So, who doesn’t want a gasless flux core wire? It ensures you the best MIG welding at a cheaper price. You’re getting all the needful features for the welding and this should be a pricey tool. But you’re getting them all in a very less price.

Since it is a gasless welding wire, but it offers you the smoothest feeding wire. There is less splatter and greatly welds thin and mild metals.

You can perform everything from home types welding to the industrial automobile repairing welding tasks with it.

Slags are hardly produced and you can easily remove them.

Pros

Cons

Did you ever think to have a copper-coated mild steel wire? Whatever copper-coated things are durable in terms of providing heavy-duty tasks. It has manufactured with manganese and silicon deoxidizers. This is a little bit pricey but worthy to be in your tool collections.

This works extremely great for the single or multiple pass welds. If you want to work on mild steel fabrications, then this one is perfect for you. The wire has the most flexible longevity and runs without any damage. It runs smoothly and makes your welding experience better than ever.

To weld rusty, painted, or oily materials, you will love its great performance.

Pros

Cons

What Is A Flux Cored Wire?

Flux core wire is a special type of wire that welds materials. Flux core is specially a filler material. Flux core arc is a special method applied to the arc welding process. So, it requires a constant-fed consumable tubular electrode that contains essential variables (flux, voltage, power supply).

Types Of Flux Core Wire?

There are two types of the flux core wire. Gas-shielded and self-shielded are mainly used for arc welding.

Both of the types have one common feature and that is gas-shielded. And they produce slag which helps the welding process to be cool.

Remember one thing, you always have to remove the slag when you’re done with your welding tasks in the self-shielded.

The gas-shielded flux-core wire doesn’t require any gas for welding. And they are a little bit complicated to use. So, beginners should not start their welding with it. Gas shielded flux wire is eligible to use in the heavy-duty repairing and manufacturing tasks.

Things To Consider Before Buying The Best Flux Core Wire

Well, you’ve already decided to buy a flux core wire for your MIG welding. From our top 10 flux core wire reviews, you’ve gained most of the knowledge about the advantaged and features of them.

But how to select the best one is always a mindful hassle for you.

So, there are some things that you must need to consider and we are going to discuss them.

Why Are You Buying It?

First of all, ask yourself “why are you buying a flux core wire?” Is this your first time you’re going to use it? So, determining the expertise level, you must choose a welding wire.

There are differences from beginning level wire to advanced level. If you’re just new to this world, then you must get a basic flux wire.

Budget

Sometimes a budget can be an issue when you can get all the essentials in a tool at a very low price. In that case, you don’t need to get a pricey one. But it is better to get an expensive flux wire when you’re going to deal with bigger projects.

And remember, repairing, manufacturing, automobile workshop, industrials construction sites, and ship manufacturing welds can be only done with pricey wiring. If you get cheaper wire for these welds, you may end up being in a messy situation.

What Does Your Project Need?

Looking at the project requirements, you need to select the product. There are specific tools to accomplish a particular welding task. So, you always should choose the product that fulfills the basic needs of your project.

Go For The Trusted Manufacturer

Going for the trusted manufacturer confirms the reliability, flexibility, durability, and most importantly provides helpful customer support. So, choose a well-reputed manufacturer company that has been ruling the industry for years.

FAQ About Welding flux core wire

Q1: Is there any difference between flux-cored wire and solid wire?

Ans: Yes! There are differences between them. The self-shielding flux-cored wire can run without external shielding gas. Because the welding pool has gas-flux protection to prevent the wire burning. So, this is more portable and there is no need to adjust with an external gas tank.

Q2: Which one is the better among MIG and Flux?

Ans: MIG always provides the clean and easy cut to any kind of metals whether thick or thin. MIG always require for self-shielded gas to welds materials. But flux-cored welding never requires self-shielded gas to operate welding. So, flux core is a cheaper way to weld.

Q3: Which gas to use for flux-core?

Ans: Flux core requires the combination of carbon dioxide (25%) and argon (75%). You can use argon 80% and carbon dioxide 20%. This will even give the best result.

Q4: Can flux core weld aluminum?

Ans: There is no flux core wire to weld aluminum. You will need MIG welder for aluminum materials.

Q5: How does flux core do soldering?

Ans: The flux core use fluxes for soldering, and brazing. And also occur the welding by removing oxidation and make the metals joined.

Final Words

There were out best options for the flux core wire welding. Since we’ve covered the top 10 flux core wire reviews and buying guide, you should not have any difficulty to choose the best option for you.

If you still find any difficulty or have any confusion, feel free to ask us in the comment section below. So, enjoy happy welding!

You can even share with us your stories of welding that may make some sense to our constant readers.

Awesome! No words. You always go one step beyond.

There is so much great, useful information here. Thank you! Thank you! Thank you!

Thanks again 🙂