The welding community is growing each day. And because of how popular and accessible the machines are getting at the moment, many are thinking about picking a welding machine. Herein, one thing we can state with full confidence that, using it without knowing about the different welding positions will not be easy.

However, you have nothing to worry about as we have discussed the types of welding positions professionals implement when handling a metal fabrication project.

We kept things simple and straightforward, which means comprehending the information that we provided here should be pretty easy. And after going through them, you would be able to choose the position that suits you the best. That will eventually increase your productivity and allow you to become more competent.

Table of Contents

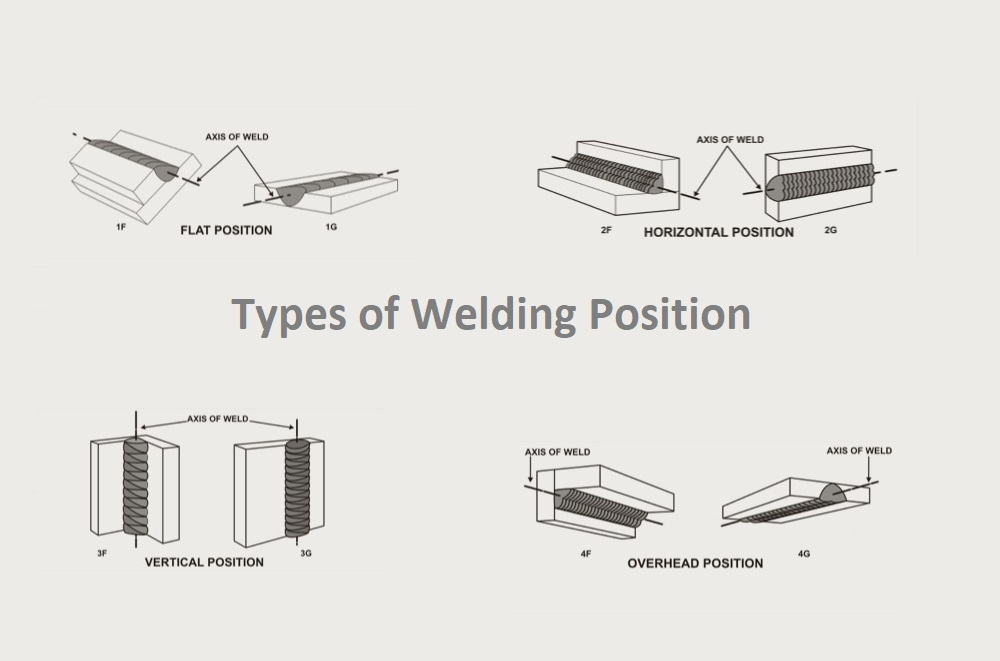

Different Types of Welding Positions

As you know by now, welding is something that is somewhat labor-intensive. And you might not always carry out the tasks in your most desirable position. If you want to get effective results, you need to consider your workpiece and select one of the four standard positions.

Now, if you are a complete newbie, you might not really know what the positions are and their names. Well, that is why we are for. We will offer you insight regarding each of the standard positions and fill you in on everything that you would want to know regarding them through our expertise. So, let us get started!

Flat Position

One of the easiest positions is the flat position. Many even refer to this one as a “down hand” position. No matter what you may call it, the thing is the same. It is often taught to newcomers because of being easy to learn. The process is simple as well. You need to work on the top side of the joint that you are working with.

As the name suggests, the workpieces are placed flat first. Then, the machine will pass through an electric arc. And it would move across through the horizontal direction. And as the top side is welded, the molten material will move downwards through the workpiece’s grooves and edges.

Horizontal Position

This position that we are going to talk about will require a bit more skill than the previous one. Welders refer to this as an out-of-position weld. And it is a bit more challenging because the position mainly focuses on the vertical side along with the overhead of the workpiece.

You might have guessed by now that you need to carry out the welding process through the horizontal axis. And the implementation of the position will highly depend on the project that you have in hand. If you are working with a fillet weld, the bead needs to be on the meeting point of the vertical and horizontal axis.

The meeting point is generally 90 degrees in angle. However, if you are working with something that requires a groove weld, the face will be exactly on the vertical plane.

Vertical Position

As there is a horizontal position, there must be a vertical position, right? Well, yes! There is a vertical position. For this one, the plate and the weld will lie vertically. However, you might face a problem when you are implementing this specific position. The molten metal will be flowing down and should be piling up.

Nevertheless, there is a solution to every problem. If you can move the position to an upward or downhill vertical position, you can easily prevent this problem. The molten metal will be flowing in that position, but it will not pile up. As a result, you will not need to stop your work and clean the pile.

Overhead

Last but definitely not least, we have the overhead position. It should be noted that this one is the most difficult position among all of the ones that we talked about. However, do not let that statement scare you off because, with practice, you can make anything easy.

That being said, the position requires you to perform the weld by keeping the pieces of metal above you. After that, you need to angle yourself and the equipment to a certain degree so that you can reach the joints properly.

One thing that you should be a bit aware of is that this position can make the metal sag from the plate. And as the metal sags, it will create a crown, which will not look good on your workpiece. But you can avoid this by keeping the molten metal puddle to the absolute minimum.

Different Types of Welds

Now that you know about the different positions that welders utilize for welding their project, you might want to know about the different types of welds as well. Worry-not, we got your back in that regard as well. There are mainly two types of welds. They are:

Groove Weld

One of the common types of weld is the groove weld. It is formed by letting the filler deposit in the grooves. And you will find them at the meeting point of two-piece of metal. Nevertheless, you can carry out this type of weld by following any of the welding positions that we described.

Fillet Weld

The fillet weld is basically the most common type among the two. You can carry this one out by fusing two pieces of metal. And the angle of the meeting point is approximately 90 degrees. That being said, you can also carry this one out by following one of the four welding positions that we have gone through.

Does Welding Positions Have Any Symbols?

You might find it fascinating that welding positions do have standard symbols. Yes! They do have dedicated symbols. So, without any further ado, let us get into introducing them to you.

1G and 1F

The 1G and 1F are reserved for the flat position. As you know by now, there are two types of welds. One is fillet, and the other one is the groove. And the F and the G corresponds to each of them.

2G and 2F

As you have guessed, these two symbols are for the horizontal position. Like the flat position, the G and the F state for the groove and the fillet weld, respectively.

3G and 3F

Following the same pattern as before, the 3G and 3F are for vertical position. The same thing that was true for the previous positions is the same for this one as well. That means the G and the F are standing for the type of weld.

4G and 4F

Last but not least, just like the pattern that we are following, the 4G and 4F are for the overhead position. As with the previous ones, the G and the F stand for groove and fillet welds.

Types of Weld Joints

You might already know what a weld joint is. Just in case you had no idea about it, it is achieved by combining two joints or two welds together. And the location where the two of the workpieces are combined is what makes them get a unique name.

With that out of the way, there are five different weld joints. Here is a small description of each of them:

Butt Joint

When two of the metal workpieces meet by touching one another’s edge, the joint is called the butt joint. This is one of the most common joints that welders utilize in their projects.

Lap Joints

This welding joint is basically the one where one of the metal workpieces meets by partially overlapping another one. As it overlaps, it gets the name lap.

T Joints

From the name, it is quite obvious that the joint will form a “T” shape. The same degree of angle that is on the corner joint is followed for this one as well. You must place the two of the workpieces at a right angle.

Edge Joints

The final type of joint is the edge joint. It occurs when you keep the flat sides of the workpieces together and weld them. Usually, the edges of the workpieces are joined, which is where it gets the name “edge.”

Corner Joint

As you might have guessed, this joint makes two of the metal meet at the corner. For that reason, the angle that the joints achieve is basically 90 degrees. This type is utilized by the welders when they require a right-angle joint on the project.

So, What Is the Best Position for Welding?

You might have noticed us stating that the position will highly depend on the workpiece that you have in hand. It will also depend on the type of weld that you are going to do. In that sense, the best types of welding position will be entirely on you. You need to choose one by factoring in the type of your project.

Final Words

We would like to hope that our expedition in describing the welding positions was a success and now you have proper knowledge about each of the types. And hopefully, you can utilize them properly to get adequate welding results.