Why do you think welding cast iron is difficult for you? It’s difficult to weld but not impossible at all. Maybe I have got the answer to your question. You might not be getting the proper welding rod to weld cast iron.

Why do you think welding cast iron is difficult for you? It’s difficult to weld but not impossible at all. Maybe I have got the answer to your question. You might not be getting the proper welding rod to weld cast iron.

Knowing the technique of welding cast iron is not the last thing. Every equipment should be matched with your requirement based on the type of cast iron.

All you need to know some information about this tiny thing is to buy effective equipment to weld cast iron perfectly. Picking the welding rod is not the real trick. Picking the right one is the key point that makes you successful.

Table of Contents

What is Welding Rod? Know Everything About It:

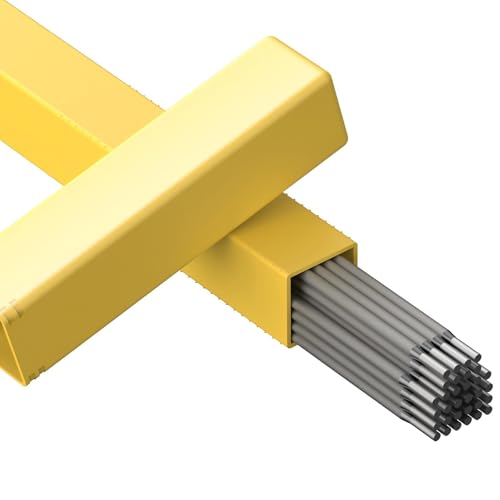

Both professional and non-professional welders know what a welding rod is. It comes as a form of stick that is used to join different types of material. The most common use of the welding rod is for shielded metal arc welding.

It’s also known as electrodes or fillers as well. In the professional’s welding cart, you’ll find different welding rods. Different because the welding rod acts differently based on its building method.

Some of them are consumable and some are not. The main characteristic of a consumable welding rod is, it melts to make a bond with other materials like cast iron.

On the other hand, a non-consumable welding rod just makes enough catalytic reactions. It’s to propagate fusion, especially in an Oxy-rich atmosphere.

Importance of Choosing The Right Welding Rod:

So, what’ve we found? Welding rod is a combination and composition that is similar but not the same in characteristics. According to the metal and project types, you must choose the right welding rod. A variety of factors influence choosing decisions for this must-have welding kit.

As an example, stick welding rods or electrodes are highly consumable. Because the composition of material forces to be a part of the weld. On the other hand, TIG electrodes are not the same in characteristics. They are non-consumable.

Best Welding Rod for Welding Cast Iron:

Based on the use of different cast iron you must use a different welding rod to get a better result. We tried to classify welding rods for you.

Generally, welders pick welding rod-based one three things. One is cost, the second one is machine-ability and the last one is the weld is multiple pass or single pass. Let’s check it out.

- 99% Nickel Rods or Tech-Rod 99 (AWS class ENi-CI)

- 55% Nickel Rods or Tech Rod 55 (AWS class ENiFe-CI)

- Steel Rods or Ferroweld (AWS class ESt)

99% Nickel Rods:

From the name, you might imagine where to use this rod. Its nickel-based welding rod. That means it’s expensive to use. Like the price, it’s highly machine-ability and works best on most types of cast iron. The premium material has been used to make this rod.

Besides, it’s a single pass weld that offers high admixture. For the medium or low phosphorus content, you can find other welding rods for the best result without it.

55% Nickel Rods:

This welding rod is not like the 99% nickel rods. Because of the used material on it, this rod comes as a cheaper option. It’s very economical to use, especially when you are about to weld a thick section of cast iron.

It can generate lower fusion. So, based on your working preference, you can use this rod. It acts differently in a different situation. Like it’s usually machine-able but acts like this under the condition of high admixture.

On the opposite, it becomes difficult to machine and hard as well. The positive side of this welding rod is, it’s stronger and more ductile.

Steel Rods:

To minimize the repairing cost and try to get the job done, steel rods come as an ultimate choice for both professional and non-professional welders. Yes, it’s one of the cheapest options out there for welding cast iron but it’s not machine-able.

So, you need to use grinding to ensure a better finish of the weld. It’s built for simple repairs and works as a filler.

On top of that, its characteristics don’t match with hard welds or applications that need furnished welding. But the untold benefit of using this welding rod is, it’s much more than user-friendly.

Way To The Right Welding Rod for Cast Iron

There is no specifically designed welding rod made to weld cast iron. But some specific types show a great result when welding this material. You can make sure you have got the best welding rod that is soft and machine-able.

If the welding rod has a high amount of nickel, copper, and other material that means this is the one you need to weld cast iron. Getting the welding rod of steel core means you got the cheaper one.

Experts suggest using a 55% nickel rod. This rod will show better results and ensure fewer weld cracks than the 99% nickel rod. If you don’t need any welding rod that is machine-able then goes for the steel rod.

Remember, a perfect combination of welding rods with the welding technique can make a strong bond on cast iron. Sometimes you might face a problem with temperature management. Using the right welding rod like a nickel rod can be the solution to this problem.

Some rod has nickel-based core flux that means it ensures high-quality weld. In statistics, we found, many professionals use pure nickel and nickel-iron electrodes to rapid cast iron.

Conclusion:

As one of the most popular metal cast iron got a huge platform in the metal industry. So, cast iron has been used in lots of complicated, sensitive, and highly engineered applications. But this is not the end of the journey of cast iron.

It can break and crack as well. So, what do we do? Weld! Even you need the most perfect skill and equipment like a welding rod to do it.

That’s why we talked about finding the perfect welding rod to weld cast iron. Based on your need, now you can pick the right welding rod for cast iron. Happy Welding!